THE NEW STANDARD

FOR CONCRETE COATINGS!

Midwest Concrete Coatings is an experienced company in the Omaha, Lincoln, Council Bluffs, Rapid City, SD areas, and a fresh face to the Kearney, Grand Island and Lexington area.

We offer the most advanced concrete floor coating technologies available on the market to protect and enhance the look of your garage, patio, basement, pool deck, or commercial space.

HOW IT WORKS

Our expert team helps you find the correct floor coating for your needs. From garage coatings to commercial buildings, we can help transform your concrete space into something that looks and feels luxurious that will last for years to come. Our product has superior technology and advanced chemistry that we stand behind with our Lifetime warranty.

OUR SIX STEP PROCESS

-

STEP 1: FLOOR PREP

To ensure a proper bond, the concrete floor must first be prepared. We use diamond grinders with integrated vacuum systems to ensure a perfectly smooth surface that is free of dust and debris and ready for our basecoat.

-

STEP 2: APPLY MENDER

One of the best features of our concrete coating is that it can essentially repair an old, cracked concrete slab. That’s because we use menders and fillers to repair cracks and spalls in the existing floor before ever applying any coating.

-

STEP 3: APPLY BASECOAT

The first coat of self-priming polyurea is applied. This coat bonds securely to the floor, ensuring that it won’t ever peel up, even if it is exposed to intense pressure, drastic temperature changes, or even corrosive chemicals.

-

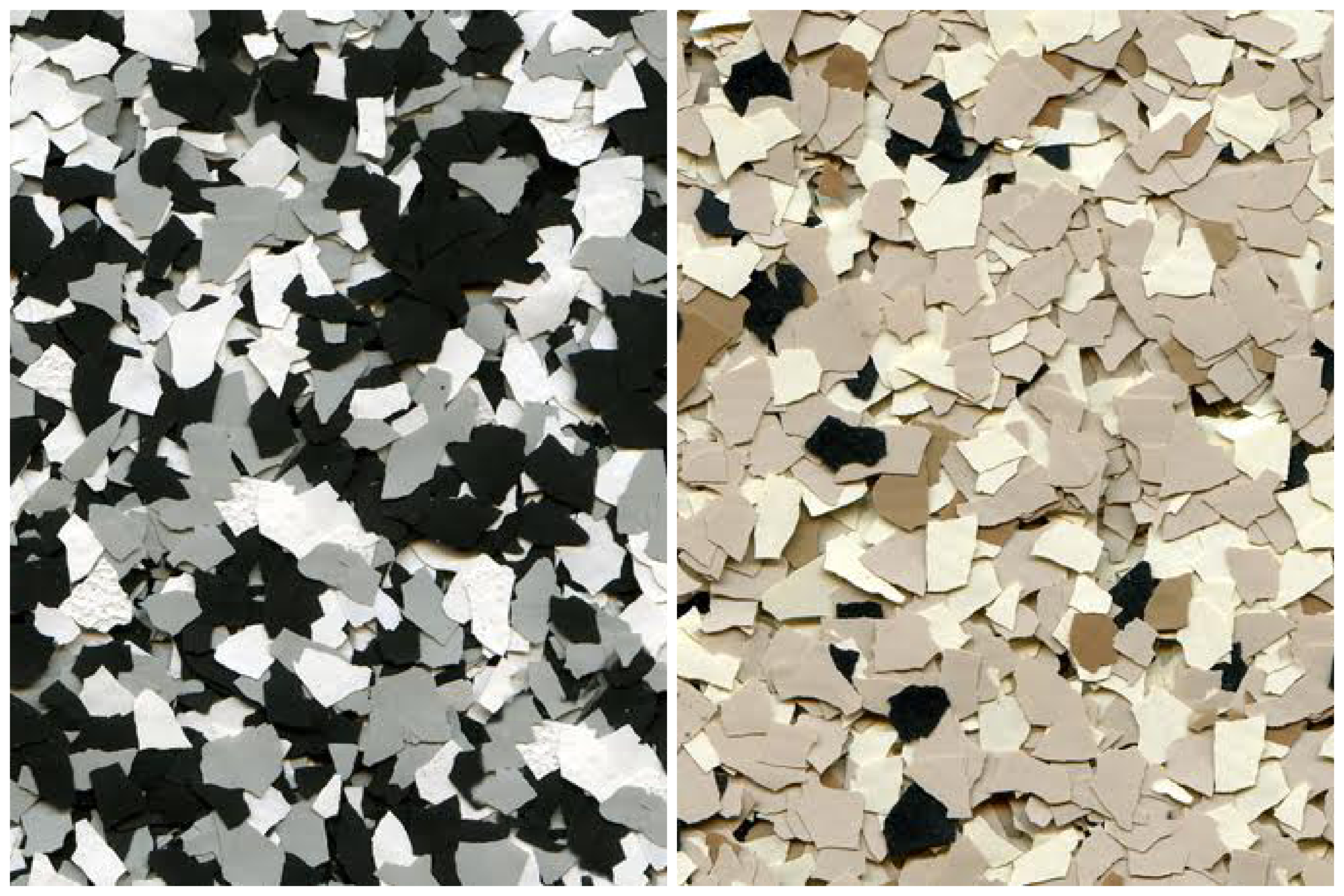

STEP 4: BROADCAST CHIP

Next we scatter multi-colored vinyl chips across the floor by hand. This provides texture to the floor and creates a gorgeous mosaic. We offer numerous color combos to choose from to help create the perfect look for your space.

-

STEP 5: SCRAPE FLOOR

After the basecoat has cured, we scrape off the loose flakes twice . Afterwards, we leaf blow and vacuum the floor to prepare it for the final coat.

-

STEP 6: APPLY TOPCOAT

This clear layer of polyaspartic serves as armor to protect the floor against natural wear and tear, such as scuffs, sharp impacts, and chemical spills. This layer is fully cured and ready for minor foot traffic within 6 hours and can return to full use within a day.

With over 16 full flake color options to choose from, you will be sure to find the perfect concrete coating color to match the look and feel of your space!